Machine fleet

We have a complete, modern and efficient machine park that allows us a high vertical integration of our production: 3 or 5 axis numerical control machines (CNC), welding machines, tube benders, cut-off machines, lathes and calenders, as well as to an automated vertical warehouse where we maintain stocks of extrusions. Most of our machines have the “Industry 4.0“.

Welders

# 1 SIMULO SOYER WELDING MACHINE

Automatic welding center for stud bolts from M3 to M8 in aluminum - YEAR 2021

The machine is equipped with:

- N°1 SOYER BMS10P WELDING MACHINE

- N°1 SOYER SK-5AKS WELDING HEAD for contact welding and lifting

- N°1 SOYER UVR-300 PROJECTION PIN FEEDER

- N°1 SIEMENS HMI9” CONTROL PANEL

Welding range: 2500x1500mm

Pipe bend

# 1 CNC E-TURN 52 ELECTRIC • YEAR 2020

Right and left bend in process, with fixed and variable radius, in single or multi radius UP TO ø50.8mm.

- Flexible and fast to be suitable for any type of application, from furniture to automotive.

- Freedom of shape: with round, oval, rectangular tube, pre-worked with holes and slots.

- Freedom of radius: fixed and/or variable.

- Freedom of orientation: flat, sideways, with inclined section.

- Freedom in the sense of curvature

VGP3D programming software with three-dimensional graphics:

- Check real feasibility of pieces

- Real cycle time calculation in advance, reducing quotation and customer response times

- Automatically cyclic machine generation

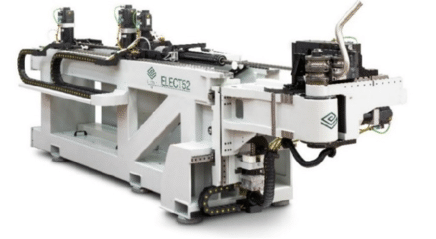

# 1 CNC ELECT 52 ELECTRIC • YEAR 2023

Right and left bend in process, with fixed and variable radius, in single or multi radius UP TO ø50.8mm.

- Flexible and fast to be suitable for any type of application, from furniture to automotive.

- Freedom of shape: with round, oval, rectangular tube, pre-worked with holes and slots.

- Freedom of radius: fixed and/or variable.

- Freedom of orientation: flat, sideways, with inclined section.

- Freedom in the sense of curvature

VGP3D programming software with three-dimensional graphics:

- Check real feasibility of pieces

- Real cycle time calculation in advance, reducing quotation and customer response times

- Automatically cyclic machine generation

Calenders

Numerical Control Machines (CNC)

5 AXIS CNC

#1 MAZAK VCN 530C • YEAR 2023

Latest generation vertical machining center for a wide range of applications, from heavy chip removal machining to high-speed milling operations.

TECHNICAL FEATURES

Capacity:

- Table length 1,300 mm

- Table width 550 mm

- X axis travel 1,050 mm

- Y axis travel 530 mm

- Z axis travel 510 mm

Spindle:

- Spindle power (5 min) 18.5 kW

- CAT 40 tool holder

- Maximum rotation speed 12,000 min-¹

- 30 tool magazine (ISO40)

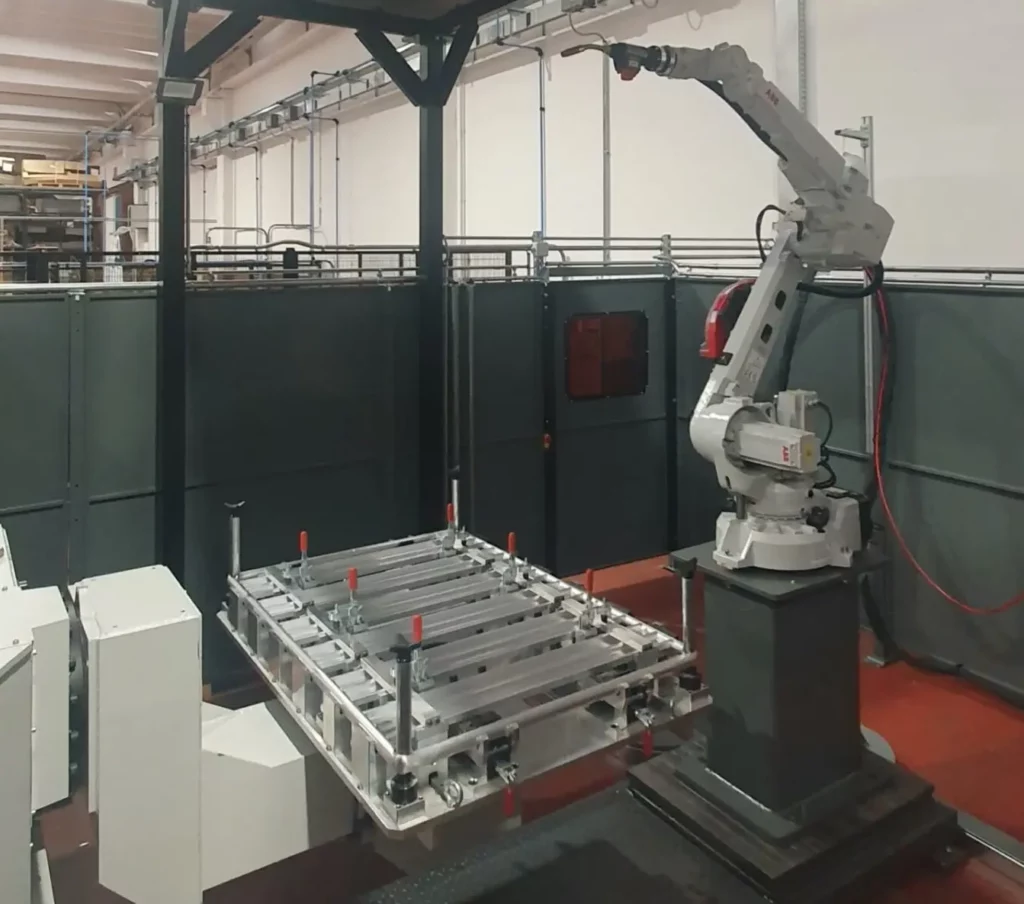

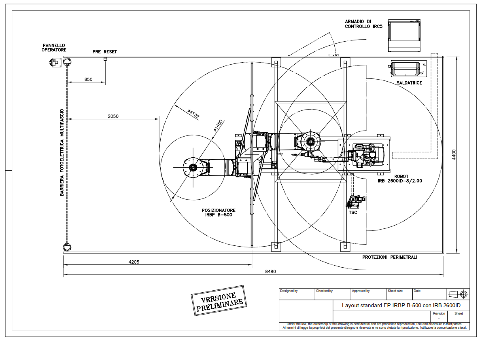

#1 MAZAK CV5-500 + ROBOTIC ISLAND • YEAR 2023

5-axis vertical machining center with gantry structure and rotary-tilting table, which offers high rigidity for high-precision machining.

Designed to provide high-speed, high-precision machining and simplified use. The CV5-500 sets a new standard for 5-axis machining, with maximum added value.

- Tilting rotary table with “Roller Gear Cam” transmission system for B/C axes and linear roller guide on X, Y and Z axes

- High Rigidity Spindle 18,000 rpm 18.5 kW/119.4 Nm (10% ED)

- 48-tool magazine with high-speed tool changer (Chip-to-Chip 1.3 seconds)

- Minimum floor space with lateral chip conveyor

- High performance MAZATROL SmoothX numerical control guarantees exceptional five-axis machining results.

- Table working range Ø500 h.320mm

- Renishaw RMP600 probing probe

- Robotic island with tray drawer unit and 6-axis robot with 25kg capacity

#2 EMMEGI COMET R4 • YEAR 2020

5-axis machining centre, designed to perform machining on bars or pieces up to 4000mm in length.

The 4th and 5th axis allow the electrospindle to rotate continuously by CN from -15° to 90° on the horizontal axis and from -360° to +360° on the vertical axis.

Tool magazine with 12 places, on board the X-axis carriage, capable of also hosting a disc cutter.

The machine software, depending on the length of the piece and the machining to be performed, is able to determine, in absolute safety, the positioning quota of each vice group.

Rigid tapping up to M10

- Maximum power in S1 (kW) 8.5

- Maximum power in S6 (60%) (kW) 10

- Maximum speed (rpm) 24,000

- Profile length dimensional gauge

- N°8 independent motorized vices

#1 SATELLITE EMMEGI XT L=7800mm • YEAR 2016

5-axis CNC machining center with mobile gantry, designed to carry out machining on bars or large pieces.

High power electrospindle (15 kW in S1) with HSK-63F tool attachment.

Tool magazine with 16 places.

The 500 mm blade tool is housed separately in a dedicated magazine.

- Possibility of using the center in commuter mode.

- Cutting and separation function

- Rigid tapping up to M12

- Probing with RENISHAW instrument for precision machining

No. 8 vices

#3 EMMEGI COMET R4I • YEAR 2023

5-axis machining centre, designed to perform machining on bars or pieces up to 4000mm in length.

The 4th and 5th axis allow the electrospindle to rotate continuously by CN from -15° to 90° on the horizontal axis and from -360° to +360° on the vertical axis.

Tool magazine with 12 places, on board the X-axis carriage, capable of also hosting a disc cutter.

The machine software, depending on the length of the piece and the machining to be performed, is able to determine, in absolute safety, the positioning quota of each vice group.

Rigid tapping up to M10

- Maximum power in S1 (kW) 8.5

- Maximum power in S6 (60%) (kW) 10

- Maximum speed (rpm) 24,000

- Working range X=3475MM Y=300MM Z=250MM

- Profile length dimensional gauge

- N°6 independent motorized vices

- Probing with ReniShaw probe

#2 EMMEGI XTE • YEAR 2023

5-axis CNC machining center with mobile gantry, designed to carry out milling, drilling, threading and cutting on bars or large pieces in aluminium, PVC, light alloys in general and steel. The mobile part of the machine consists of a portal equipped with precision rack motorization. The high-power electrospindle (15 kW in S1) with HSK-63F tool attachment allows you to carry out even heavy-duty machining operations with excellent results in terms of speed and precision.

The 24-place tool magazine, housed in the mobile portal, is equipped with an exchanger arm system which considerably reduces tool change times. The 500 mm blade tool is housed separately in a dedicated magazine.

- Possibility of using the center in commuter mode.

- Cutting and separation function with motorized vices

- Rigid tapping up to M12

- Probing with RENISHAW instrument for precision machining

N°10 independent motorized vices - Fifth wheel tool magazine with arm exchanger with 24 tool places + 500mm blade

- Working range X = 7800MM Y=1000MM Z=400MM

3 AXIS CNC

#2 MAZAK VTC760C • YEAR 2020

The high rigidity structure together with a high power spindle guarantee high precision performance and increased productivity.

The 2300 mm table and the design of the mobile upright offer exceptional versatility, allowing the easy processing of large pieces even higher than the table top or protruding beyond it.

Latest generation numerical control MAZATROL SmoothG

Miter saws

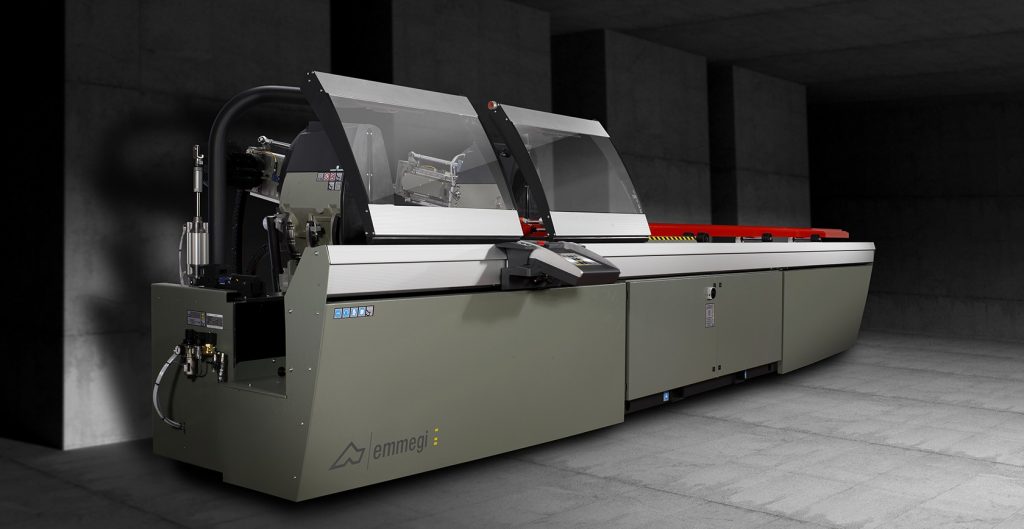

# 1 EMMEGI EMMEGI PRECISION TS2 L=5000MM • YEAR 2019

Double-head cutting-off machine with 3 controlled axes with automatic movement of the moving head with management of angles within the range of 15° external and 45° internal.

Blade advancement by oil-automatic cylinders.

550mm blade

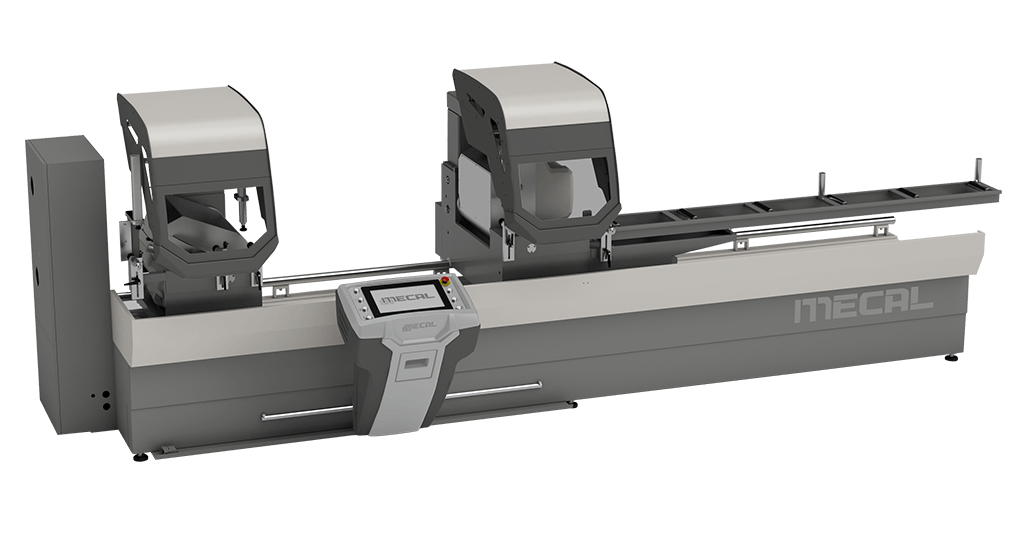

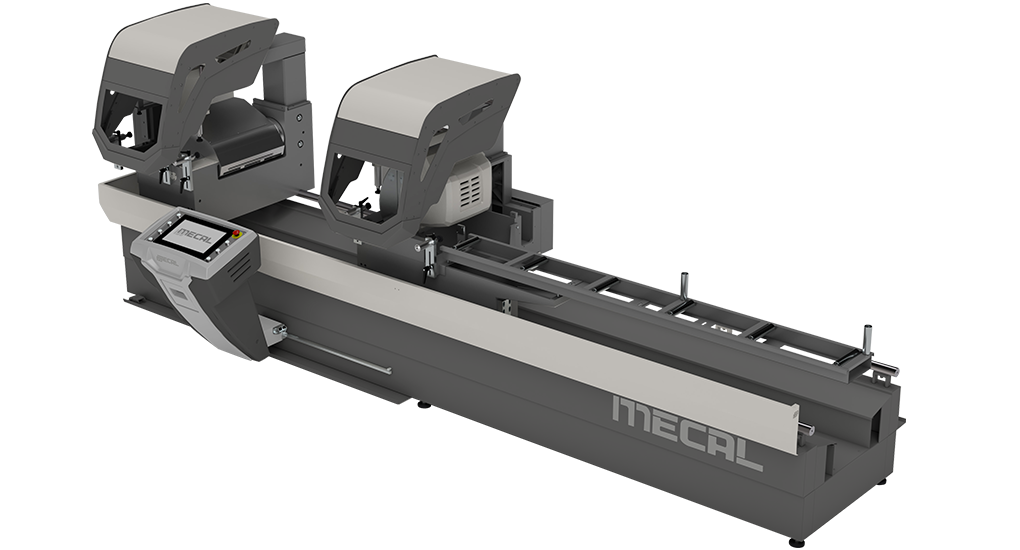

# 1 EMMEGI 50 AUTOMATIC • YEAR 2019

Automatic cycle miter saw for 90° cutting with mechanical stop advancement system, with length adjustment and cutting tolerance up to 0.1 mm.

Pneumatic system for automatic separation of the piece to guarantee the maximum quality of the cut surface.

The blade advancement can be pneumatic or hydraulic, the latter making the machine particularly suitable for processing large-section profiles.

Come back

# 1 MOMAC TA 20 • YEAR 2020

The TA Series CNC lathe machines are particularly suitable for processing single or medium-small pieces of any detail and of any type, shape, size and weight (from the simplest to the most complex), the range presented by us is probably the most complete currently available on the market.

Vertical warehouse

# 1 VERTICAL WAREHOUSE 13 MT

We have a modern vertical warehouse

• To manage the stocks of extruded bars, a double automatic warehouse has been adopted

• An external tower 13 meters high, divided into drawers, allows you to manage bars up to 8 meters long and a total stock of up to 350 tonnes of extrusions

VISIT ALUPROJECT!

Click on the red button to take a virtual tour of our factory! Interested? Contact us and we will gladly welcome you into our technical, commercial and production spaces

Contact us without obligation for an inspection of Aluproject.

We will make one of our technicians available to you as soon as possible!

Products from aluminum profiles and extrusions for the residential furnishing sector (living areas, bedrooms, bathrooms, kitchens, SPA and wellness areas), community and public space furnishing (theatres, schools, universities, hospitals, courthouses), lighting (indoor and outdoor), industry (medical, automotive, railway, aviation)