Aluproject's Services

Aluproject proposes itself as single interlocutor for its Customers. We take care of all the production phases, from the analysis of the client's commercial needs up to the shipment of the finished product (including design, industrialization, prototyping, manual and automated mechanical processing, quality control, and packaging). We carry out production activities with high vertical integration, thanks to the support of the Agnelli Group's subsidiaries Alugreen, Trafileria Alluminio Alexia, Alucolor.

01

Customer Needs Analysis

We analyze the production, stylistic and material needs of our customers to define the most effective and efficient production, packaging and shipping choices.

The objectives of the preliminary analysis phase are:

- Identify the most appropriate technical solutions

- Minimize total design, manufacturing and logistics costs

- Define a quality control and delivery plan

02

Design and Prototyping

Our technical office, thanks to the support of MOST ADVANCED THREE-DIMENSIONAL DRAWING PROGRAMS, quickly develops complex systems and products with high precision (drawings, prototypes and tests according to applicable international standards).

In particular, we use the following design software:

- SOLID WORKS PROFESSIONAL 2019 + SIMULATION (Possibility to perform static load simulations on assemblies, fatigue study and topological study)

- CAD CAM CNC PROGRAMMING INTERFACE WITH PUMA CAMALEON SOFTWARE FOR INTERPOLATION PROCESSING (5-axis Emmegi machining centres)

- EMMEGI CAM PLUS SOFTWARE + DRIVER CAD

- MECAL CAD LINK SOFTWARE

03

Industrialization and Raw Material Purchases

Industrialization:

In the industrialization phase, we carry out the study of the matrices for the production of extrusions, the optimization of the work cycles and the setting of the automatic machines dedicated to the various processes, the product quality control plan with the objectives of reducing production costs and minimize the total-throughput-time of the process.

The superior industrialization skills of Aluproject's technical team are the basis of the company's competitiveness, especially in the case of mass production.

Raw Material Purchases:

We source the raw material from our subsidiaries Alugreen and Trafileria Alluminio Alexia:

• Alugreen is the foundry that produces aluminum billets.

• Alexia, thanks to an automated system, transforms the billets into an almost perfect semi-finished product. Four modern presses of 1800, 2200, 3000 and 4500 tons guarantee a wide range and production capacity. The high variety of alloys available allows us to satisfy the requests of any production area.

Belonging to a solid group specialized in the production and transformation of aluminum allows us to:

– supply the raw material at competitive prices

– guarantee continuity of supply in every market situation

– maintain quality standards over time

– respond quickly to every need of our customers

04

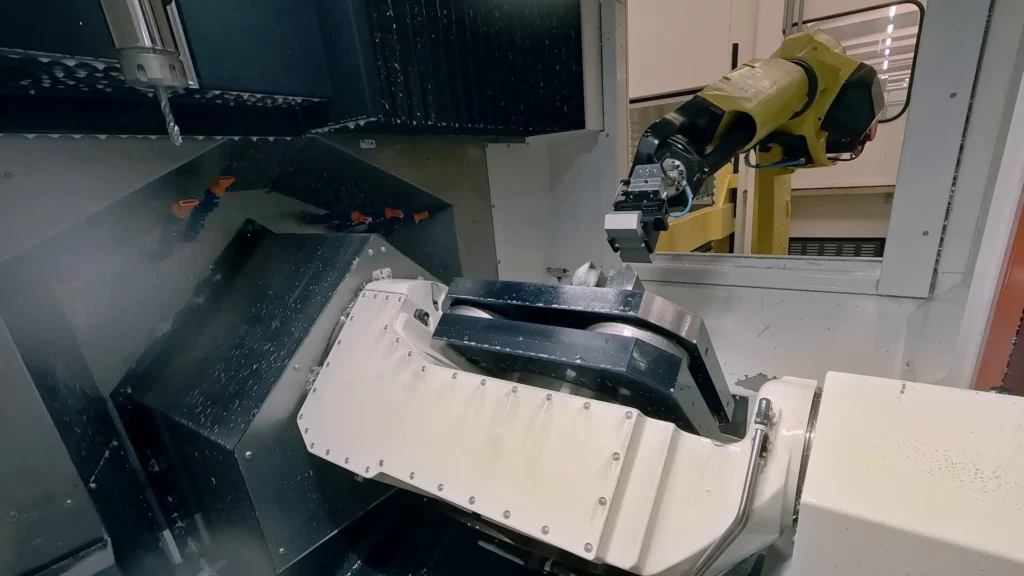

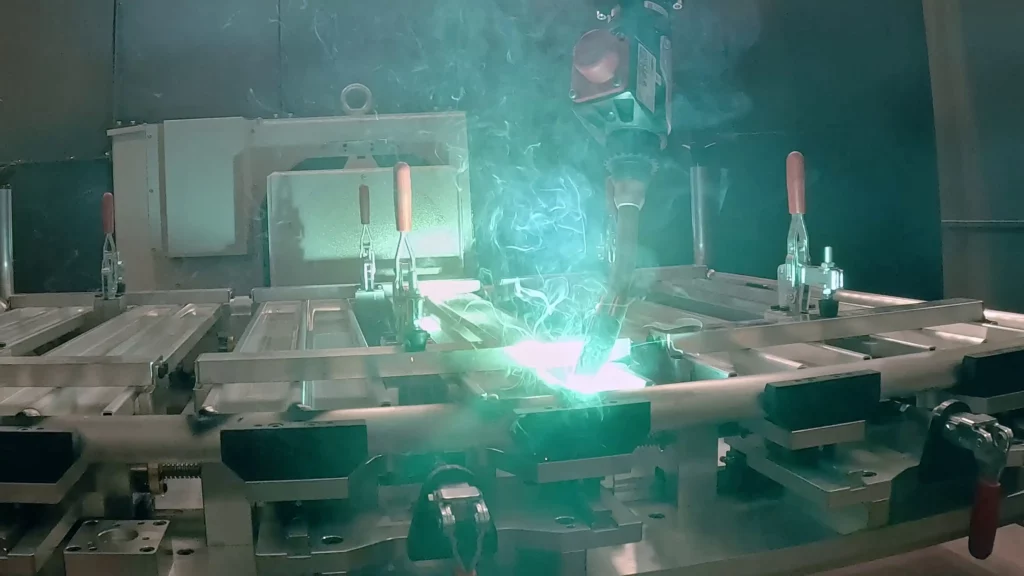

Mechanical Machining

We carry out all the necessary processes on semi-finished products, mainly in an automated way:

• Cutting and shearing

• Mechanical machining (with 3 and 5 axis CNC machines), i.e. milling, threading, drilling

• Bending with numerical control machines (calendering, folding, cambering, stretch bending)

• Robotic MIG welding

05

Aluminum Surface Finishing

We are able to carry out, through our sister company Alucolor and a network of subcontractors, infinite finishing solutions for aluminum surfaces, with both painted and anodized colours:

PAINTING (by piece and/or bar)

- Dust

- Liquid

- Pigmented Transparent Liquid

- Masking service

ANODIZATION (by piece and/or bar)

- Matt treatment up to 7000mm

- Brushed matt treatment up to 7000mm

- Brilliant treatment up to 4200mm

- Brilliant brushed treatment up to 4200mm

- Special finishes up to 4200mm

- Electro color up to 6000mm

- Manual and robotic mechanical cleaning treatment and pre-treatment

- Brushing treatment

- Phospho-chromation treatment

CHROME PLATING

- Polished chrome

- Black chrome

VENEER

DIP-PRINT

06

Assembly, Quality Control, Packaging and Shipping

Assembly

Our know-how, our history, the experience of our collaborators gained over the years, allows us to carry out the assembly of details of any complexity. We use multiple fixing systems to assemble profiles and extrusions into finished products, such as:

• Special structural or double-adhesive glues

• Insertion of pins, threaded bushes, helicoils

• Welding of aluminum projection studs

• Use of expansion systems for the assembly of tubulars without the use of visible screws

• design and creation of dedicated matrices for coupling individual pieces.

Quality check

All pieces are checked both dimensionally and aesthetically by our operators, coordinated by the Quality Manager

The Quality system, thanks to the high integration in the companies of the Agnelli group, is guaranteed both for the activities carried out in Aluproject and for the activities carried out in the subsidiaries of the Agnelli Group.

CUSTOMIZED PACKAGING SOLUTIONS

Our experience allows us to study tailor-made solutions to satisfy the protective and handling needs for all types of products:

Solutions for internal packaging with dedicated shapes in various materials:

• Cardboard

• Corrugated cardboard

• Polyethylene

• Foam rubber

• Shock-absorbing profiles

External shipping solutions:

• Packaging in customized crate (fumigated if required)

• Cardboard packaging

• Industrial packaging with boxes

• Complete and customized packaging to customer specifications

• Product handling trolleys (to reduce packaging and increase company sustainability, we have developed a system of returnable trolleys that we interchange with our customers)

We are able to deliver the products both by relying on our own vehicles (2 tractor units available for national deliveries) and by relying on couriers/shippers for international deliveries.

Contact us without obligation to evaluate your idea. We will make one of our technicians available to you as soon as possible!

Products from aluminum profiles and extrusions for the residential furnishing sector (living areas, bedrooms, bathrooms, kitchens, SPA and wellness areas), community and public space furnishing (theatres, schools, universities, hospitals, courthouses), lighting (indoor and outdoor), industry (medical, automotive, railway, aviation)