Your Design,

Our Aluminium

We design and manufacture your projects from aluminium extrusions and profiles for application in the furniture, office, industrial and lighting sectors since 2003. We belong to the Agnelli Group of Bergamo (Italy), a European leader in non-ferrous metals for over 110 years.

◽️ Design ◽️ Processing ◽️ Finishing ◽️ Assembly ◽️ Quality Controls ◽️ Shipping

Application Sectors

We manufacture customised finished and semi-finished products from aluminium extrusions and profiles for customers in the residential and commercial furniture, lighting and industrial sectors.

Aluminium parts, structures and decorations for furniture (living, kitchen, bedroom, bathroom and outdoor areas) ➔

Aluminium parts, structures and decorations for furnishing offices, communities (theatres, halls), and public areas ➔

Aluminium parts, structures and decorations for the transport, solar, medical, catering and other sectors ➔

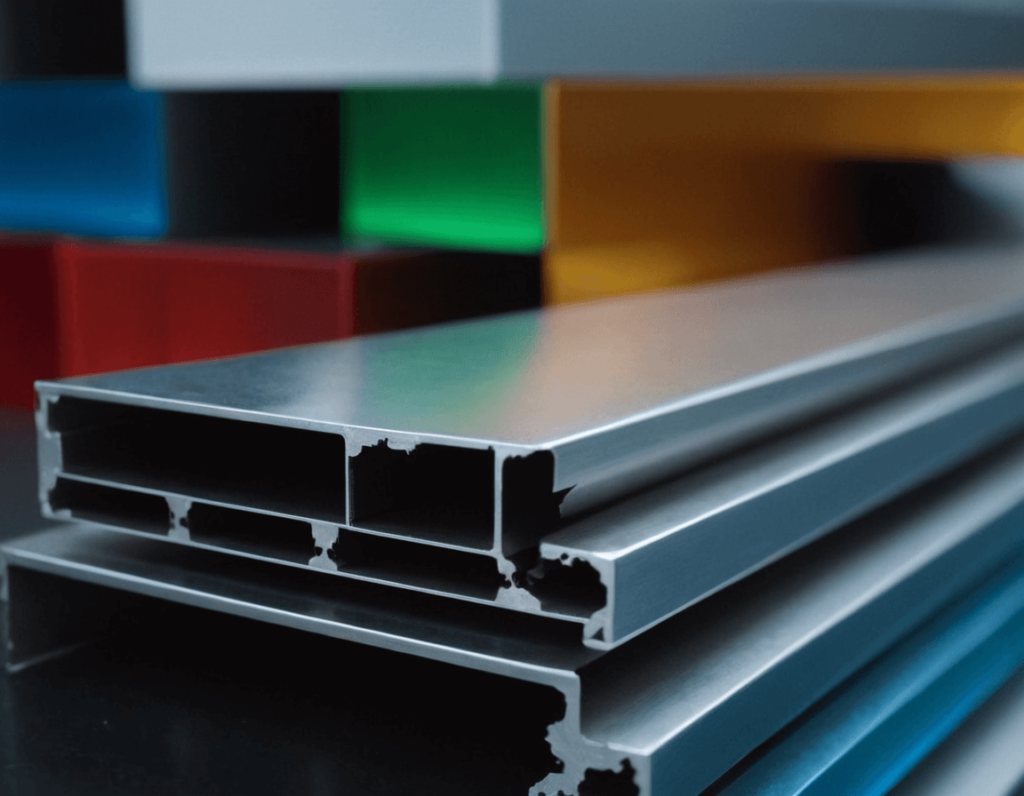

Product Examples

Our products are used as both decorative and structural elements in many applications in a wide variety of sectors. We transform aluminium profiles and extrusions into the shapes desired by our customers

Integrated Production

We have all the resources (human, technological and production) to design and manufacture finished and/or semi-finished products of any complexity from aluminium extrusions and profiles

01

We analyse the production, style and material requirements of our customers to define the most appropriate production, packaging and shipping choices

02

We design the optimal solution using a technical department equipped with the latest three-dimensional design (CAD, Solidworks)

03

We industrialise the most efficient production solution in terms of lead time, cost and quality; we purchase raw materials

04

We carry out mechanical processes manually and/or automatically (cutting, bending, bending, welding, milling, threading, etc.)

05

We can carry out infinite finishing solutions for aluminum surfaces, with both painted and anodized colours

06

In the final production phase we assemble the finished products, check their quality, package them and, finally, send them to their destination

Agnelli Aluminum Group

Aluproject is an operational unit of the Agnelli Group of Bergamo (Italy), one of the undisputed leaders at European level in the production and processing of aluminum and other non-ferrous metals

Trafilerie Alexia

The Trafilerie Alluminio Alexia, which uses large automated systems, has been producing aluminum profiles and extrusions for over 110 years

Alu Green

Alugreen is a foundry specialized in the production of aluminum billets. The annual output exceeds 30,000 tons. Eco-sustainable alloys with more than 80% recycled material and LEED certification can be supplied.

Agnelli Metalli

Agnelli Metalli has been selling ferrous and non-ferrous metals for over 60 years: aluminium, copper, brass, stainless steel, lead (raw materials and semi-finished products).

Alucolor OX

Alucolor operates in the finishing of semi-finished aluminium products. The accuracy of the production cycles and the quality of the raw materials used in the selection of colours ensure a finished product that lives up to the highest expectations.

Pentole Agnelli

The company specializes in the design, production and distribution of aluminum and copper pans, utensils and accessories for professional cooking.

FASA Pentole

There are not only pots with large professional thicknesses or exceptional creations; with Fasa, another historic Made in Italy brand, the Agnelli Group offers perfect food-grade aluminum pans useful for every daily use.

Key Numbers

Aluproject has been a solid industrial reality for over 20 years. We serve customers in Europe and Canada with a specialized, automated, and competitive manufacturing facility

Tons per year

We transform over 1,000t of aluminum extrusions and profiles per year

Clients

We deliver our products to customers in Europe, North America and Canada

Human resources

We avail ourselves of the collaboration of over 70 employees

MQ2 Productive

We operate with a modern production site of over 8k m2

FAQ

Requests

frequent

Who are you and what products do you make?

At Aluproject we create finished and/or semi-finished products on behalf of third parties and based on our customers' designs, starting from extrusions and aluminum profiles in various primary and secondary aluminum alloys. Our customers work in the residential, community and service furniture industry, in the industrial sector (e.g. railway, airport), medical, and indoor and outdoor lighting.

The company takes care of all production phases: from the analysis of customer needs to design, to the industrialization of the product (extrusion, mechanical processing, bending, welding, surface finishing), to assembly, packaging and shipping .

Aluproject is an ISO 9001:2015 certified company (Certifying Body CSQ).

Which sectors do you serve?

Our core business remains design furniture sector. Over the years we have diversified our production towards other applications.

By way of example, we have supplied aluminum parts for:

- Furniture sector: living area (tables, sofas, bookcases, chairs and stools, accessories such as door frames, handles, feet), residential outdoor furniture (tables, chairs, sofas, sun loungers, umbrellas), kitchens (frames, legs, doors, shelving systems, drawers, shelves, handles, opening and sliding systems, guides and mechanisms), bedroom (beds, wardrobes and accessories), services/SPAs and wellness areas (profiles and handles for shower cubicles and wellness systems), accessories and complements design (extruded vases, planters, coat hangers, cellars and buckets for wine bottles)

- Office and community furnishing sector: office furniture (tables, chairs, bookcases and accessories such as, for example, cable ducts), furniture for conference and teaching rooms (seating, desks and tables for universities, courts, auditoriums and theatres), public areas (seats and benches in airports or for railway stations)

- Industrial sector: smart cities (information panels, aluminum casings for information displays and totems), furniture for the railway sector (profiles for flooring of train carriages and steps, profiles for train interiors, profiles for door structures, anti-vibration systems), aluminum details for caravaning and bicycles (verandas and awnings, extendable steps for campers, interior furnishing profiles and roof racks, bike rack joints and forks), automotive (pipes for motorcycle silencers, frames for self-driving cars and mini-cars), catering and hospital applications ( food trolleys and trays), energy sector (profiles for solar panels, profiles for absorbers and collectors, clapet valves, ventilation blades), machine tools and medical devices (frames, sliding guides), vending machines and coffee machines (machine fronts , upright and underbody profiles), naval (curved profiles, hinges and joints, interior design components)

- Lighting sector: aluminum details for indoor and outdoor lamps (design lamps and heat sinks, (lighting for gardens, streets, parks, professional lighting systems for events and shows)

What materials do you work with? Is there a minimum order?

We specialize in the transformation of extruded and aluminum profiles primary and secondary (our raw material) into finished and semi-finished products of any complexity.

Upon request we can integrate casting/die casting details, sheet metal and tubular parts (always in aluminium) into our products. We mainly machine 6060 alloy, but we can supply all aluminum alloys. The list of grades available at this link: https://www.alluminioalexia.com/leghe-alluminio-2/).

We source the raw material directly from the subsidiaries of the Agnelli Group to which we belong (billets from Alugreen, profiles and extrusions from Trafileria Alluminio Alexia). We can also process extrusions supplied by the customer on behalf of third parties.

For extruded profiles the minimum production batch is 500/1000 kg, but thanks to our vertical warehouse we can manage stocks flexibly by dividing the minimum batch over multiple monthly production batches.

We have an internal production capacity capable of accommodating both pilot series and prototypes (with a series of dedicated CNC machines) and large series production (thanks to our completely renewed CNC machine park, high automation of our processes and a qualified network of suppliers).

What sizes do you machine?

We cover the widest size range in our industry.

- Extruded: thanks to Trafileria Alexia we can supply profiles from small to large dimensions (weights from 50 grams/meter to 40 kg/meter, extruded dimensions with rectangular section up to 500×50 mm and circular sections up to a diameter of 250 mm). Alexia's 4500 press (inaugurated in 2023) is one of the 3 most important in Italy in terms of size.

- Mechanical Machining: thanks to Aluproject's fleet of machines, we can work pieces from small dimensions (LED door profiles) to large dimensions (extruded products over 6 meters in length such as outdoor lighting poles).

Do you supply Made in Italy and eco-sustainable products?

We supply products from a completely Italian supply chain: from billet casting to profile extrusion to mechanical processing: 100% Made in Italy.

We can supply eco-sustainable aluminum alloys with more than 80% recycled material and with LEED (leadership in energy and environmental design) certification.

Aluminum is in itself a material with a very low environmental impact: it is widely available in nature (it is the third element present on the earth's crust) and is easily recyclable (the energy required for recycling is equal to one twentieth of that of a new production).

First-Class Clients

We have been collaborating for decades with leading companies in their respective reference markets

Why Us?

Aluproject's mission is to design and manufacture aluminum products from extrusions and profiles of the best quality, at the most competitive cost, and in compliance with its customers' production deadlines

We find Solutions

We identify the most efficient and economical production solutions for our customers, offering ourselves as a single point of contact for all needs

We are Competitive

Belonging to the Agnelli Group we obtain supplies at advantageous conditions; process automation translates into tangible savings for our customers

On-Time Deliveries

Our "on-time delivery" is consistently higher than the 95%; we monitor our operational performance to comply with every agreement made

We guarantee Quality

We have access to high quality raw materials; We have quality control systems that minimize Non-Conformities for our customers

Contact us without obligation to evaluate your idea. We will make one of our technicians available to you as soon as possible!

Products from aluminum profiles and extrusions for the residential furnishing sector (living areas, bedrooms, bathrooms, kitchens, SPA and wellness areas), community and public space furnishing (theatres, schools, universities, hospitals, courthouses), lighting (indoor and outdoor), industry (medical, automotive, railway, aviation)