About Us

Aluproject was founded in 2003 as a division for mechanical processing of the Alluminio Agnelli group (a solid industrial reality based in Bergamo – Italy). Over the years the company has evolved, specializing in "turnkey" production for the major players in the design industry.

Alurproject has been operating from the new headquarters in Osio Sotto (BG) since 2022, in the mechanical processing district of Bergamo and close to the furniture district of Brianza.

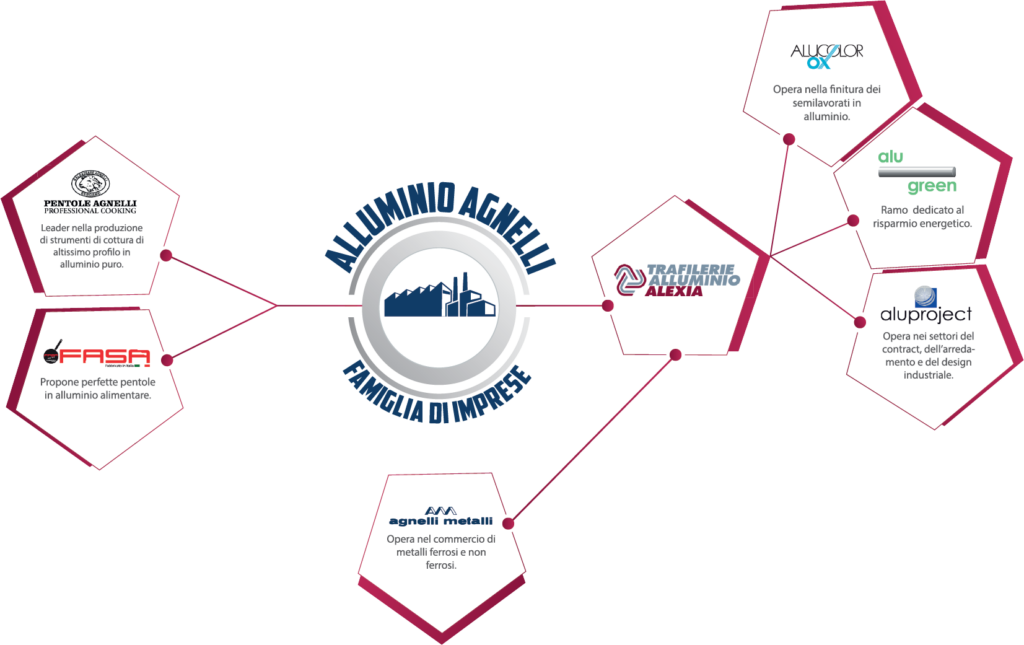

The Agnelli Group, born way back in 1907 on the initiative of Cavalier Baldassarre Agnelli, has become over the years one of the most important players at European level in the production, marketing and transformation of aluminum products.

Going through various stages of entrepreneurial development, growth and diversification within the core business of aluminium, the Agnelli Group today consists of a plurality of entities and production sites dedicated to complementary, but synergistic, aspects in the field of aluminum for civil and industrial use. The Group operates with operational units (production and commercial) based in Italy, Poland and the United States.

Aluproject's belonging to a Group of significant size allows the company to leverage extensive know-how in the aluminum sector and privileged conditions of access to the raw material: factors that increase its competitiveness in economic terms, operational flexibility, process and product quality, ability to respect the contractual terms agreed with its Italian and international customers.

THE AGNELLI ALUMINUM GROUP

Aluminum Green is a foundry that produces aluminum billets, respecting the international reference regulations. The factory, developed on a total surface area of 15,000 m2 of which 8,000 are covered, is located in the municipality of Pralboino, in the province of Brescia.

It is a "virtuous factory" with high production capacity - 30 thousand tons per year of raw bars - which stands out for the alloys made with more than 85% of recycled aluminium, of which the minimum 50% comes from post-consumer collection. This allows 95% energy savings compared to extraction production.

The Alexia Aluminum Drawing Mills, which make use of large automated systems, ensure an almost perfect semi-finished product, complying with all European standards (designed profiles, standard profiles and Alexia proprietary systems). The products of the Alexia drawing factory are accessories, hospital fittings, furnishing articles, articles for geodetics, for elevators, anode bars, for signs, prefabricated houses, electrical conduits, for construction, electronics, lighting, for machine tools, for shutters and shutters, for automatic doors, for structural profiles and tensile structures.

The company boasts a production capacity of over 40 thousand tons per year, operates with 4 large automatic presses, employs around 200 employees and makes use of a technical, commercial and operational structure spread over over 25 thousand square meters

Agnelli Metalli Spa is a consolidated commercial reality capable of offering any type of metal, in all sizes and qualities such as to satisfy every professional and industrial need: iron, pipes, sheets and laminates, AISI 304/316/ stainless steel 330, beams cut to size, aluminum and aluminum alloys, brass, copper and lead as well as hardware and insulated panels.

In addition to the Italian headquarters, Agnelli Metalli manages an operational unit in Poland which handles the distribution of ferrous and non-ferrous metals in Northern Europe.

Alucolor operates in the surface finishing of semi-finished and finished aluminum products. The accuracy of the production cycles and the quality of the raw materials used in the selection of colors ensure a finished product that meets the highest expectations. Although the processing methods use international standards that have already been defined for some time, anodic oxidation uses high-tech systems, which ensure perfect pre-treatment and full control of all phases. All this allows us to enhance the characteristics of durability, shine and chromatic uniformity of the semi-finished product.

The Agnelli Group, in over a century of history, has always managed - often ahead of its time - to give shape to the needs of chefs, working with them in synergy and combining the high quality of materials with attention to aesthetic design. Agnelli pots represent Made in Italy, a sign of quality and tradition. Agnelli joins the European AFFG (Aluminium For Future Generation) program and CentroAl Alluminio in Cucina, the consortium that brings together professional cookware manufacturers in Italy.

FASA is a company founded in the sixties that specialized in the production of cookware for professional use.

In over 50 years of experience it has developed a range of highly specialized products capable of satisfying the needs of hotels, restaurants and communities.

CAF Rambaldi srl, a commercial company specialized in the furniture hardware and accessories sector, presents itself as a point of reference for companies in the sector.

We offer various items ranging from the simplest furniture hardware to the most modern innovative solutions, from furniture accessories (such as LED lighting products) to quality furnishings.

Elementi is a CAF Rambaldi company that studies, designs and produces aluminum tables, chairs and furnishing accessories.

Specializing in designer furniture, it deals particularly with non-standard and customized sizes, supplying the most renowned Italian furniture makers.

Elementi constantly collaborates with Aluproject to which it entrusts the production of aluminum structures with a 100% made in Italy production.

Agnelli Complements distributes professional equipment from well-known global manufacturers with a prestigious catalog dedicated to the Horeca sector with over 1,000 references ready for delivery. The products that make up the Agnelli Complements catalog are specific and researched by industry experts for the professional world and designed for high-stress jobs. Strengthened by this cultural and professional background, Agnelli Complements offers high quality, practical and functional products, with an impeccable style, with a 360° professional service.

HISTORY OF THE AGNELLI GROUP

The story of the company's history by Paolo Agnelli, 2012

Interview with Baldassarre Agnelli

Contact us without obligation to evaluate your idea. We will make one of our technicians available to you as soon as possible!

Products from aluminum profiles and extrusions for the residential furnishing sector (living areas, bedrooms, bathrooms, kitchens, SPA and wellness areas), community and public space furnishing (theatres, schools, universities, hospitals, courthouses), lighting (indoor and outdoor), industry (medical, automotive, railway, aviation)